Supply Chain Business Network

SCOPE is for Supply Chain what Social Media is for people

Discover and connect with organizations within the SCOPE network

- Invite partner organizations to join the platform

- Connect with organizations : request connections, accept connection requests

- Manage the lifecycle of the business relations

- Assign responsibility (users with roles) to business relations

- Seamless communication with connected Supply Chain partners

Content Sharing with Supply Chain Partners

- Publish Products on SCOPE network

- Search for Products based on GS1’s GPC classification, Certificates etc.

- Discover Raw Materials, add to catalog

- Manage the lifecycle of Raw Material relations

Seamless and secure communication with connected Supply Chain partners

Interface with Organization’s ERP / Procurement systems

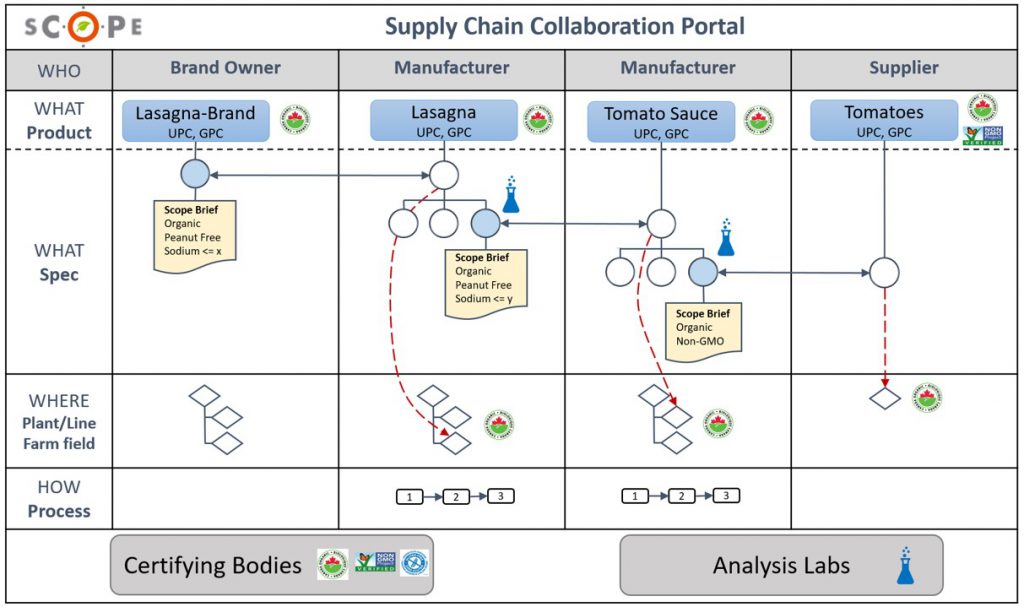

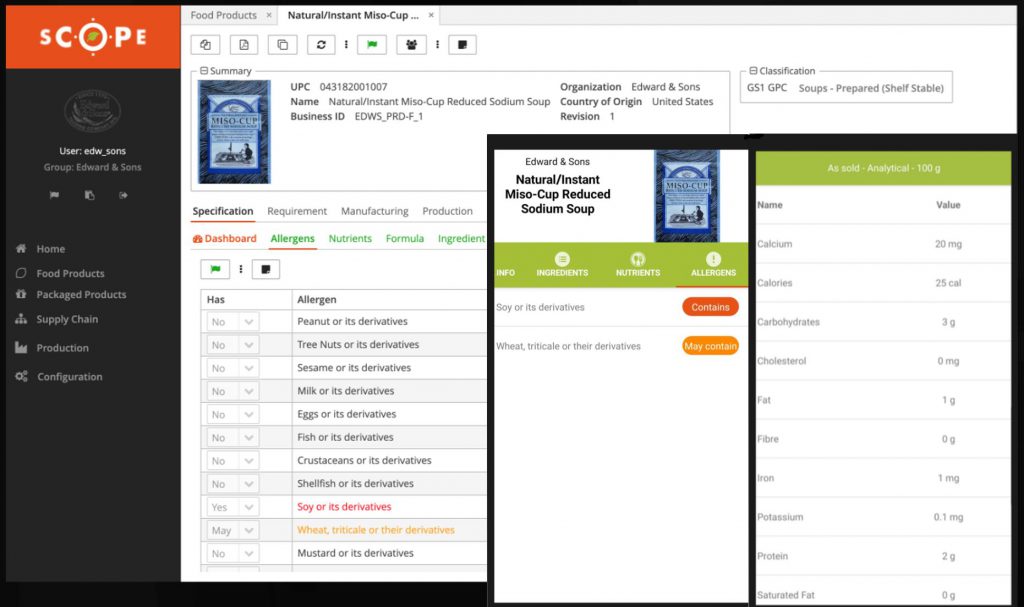

Collaborative Product Definition

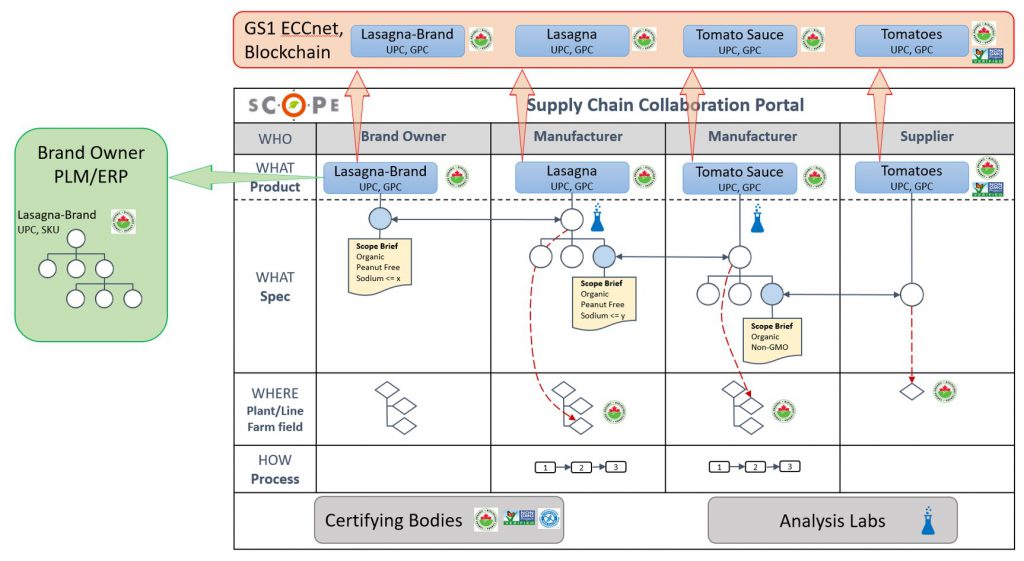

Product Definition is achieved by aggregating Product Master Data at all levels of Value Chain

- Value Chain participants (tenants) define and maintain Organization Master Data (Facilities, Brands, Users, Groups, Ingredients Catalog etc)

- Lean and streamlined Collaborative Product Definition processes enable the participants to author, publish and consume rich and accurate Product Master Data

- Formula, Ingredients, Allergens, Nutrients, Certificates etc

- ‘Flow Revisioning’ – powerful, flexible and transparent Revisioning mechanism allows for managing the Product Master Data revisions at spec level (fine-grain)

- Ability to retrieve and configure Product Master Data for any historical approved configuration

- Change Management process across Supply Chain

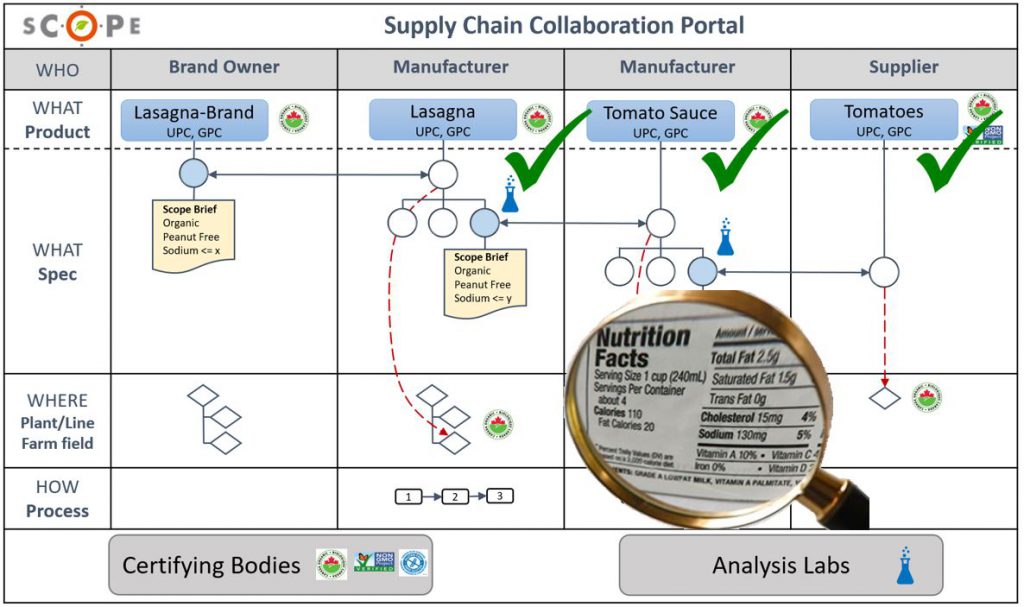

Transparency, Compliance

Transparency between trading partners enables Collaboration, Compliance validation and Trust

- Business relations (Customer-Supplier, Customer-Raw Material etc) are active, having lifecycle/states managed thru Business Process (workflows)

- Validated business relations enable Supply Chain partners to securely share and aggregate Product, Organization and Plant Master Data at all levels, thus enabling transparency and trust, and eliminating data duplication

- ‘Democratization of Data’ – Master Data is available to WHO needs it, WHEN needed, WHERE needed, while obeying Data Security and Intellectual Property

Compliance is enabled by transparency, enforced by workflows and validated throughout the process (*)

- Supplier Compliance

- Plant compliance

- Raw Material (Product) compliance

(*) There are QMS platforms/solutions for FSMA readiness and GFSI compliance, implementing HACCP, HARCP and other food safety processes – SCOPE can easily integrate with these platforms in order to provide a comprehensive compliance validation

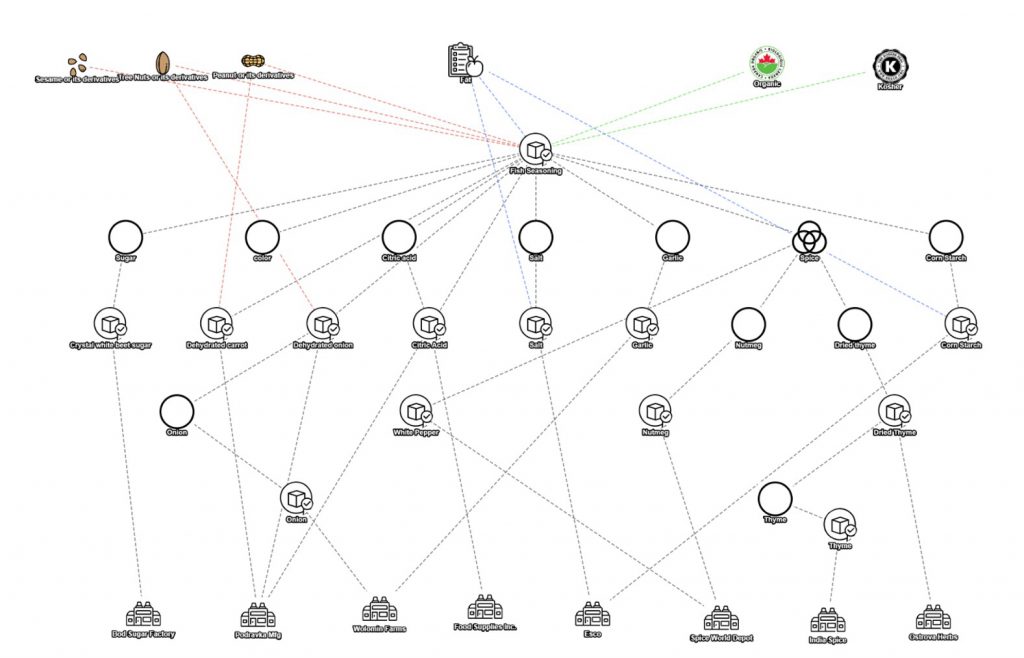

Intelligent Analytics and Optimization

Big Data, Graph Analysis and powerful Intelligent Algorithms

Unlock the value of Data with Graph Technology and AI

- Intuitive interaction with Data

- Graph transforms Data into Information and Knowledge

- Graph + AI = Insight

Big Data Analysis and Intelligent Algorithms applied to the Supply Chain Master Data (trusted) are opening endless possibilities – here are just a few examples:

- Smart Claims – identify and suggest claims that can be made on a Product by analyzing Supply Chain data at all levels (down to farm)

- Product Match Score – match all products that comply with certain profile (ex. ‘Paleo Diet’, ‘Keto Diet’ etc)

- Product Composition Optimization (ex. ‘Sodium reduction’)

- Raw Material (Ingredients) Discovery (ex. ‘Find Organic and Non-GMO Tomatoes within 100 km’)

- Supply Chain Optimization (ex. ‘Only local suppliers’)

- Product historical evolution, Genealogy report

- What-If scenarios (ex. ‘What is the impact if I change a Supplier?’)

- Predictive Analysis, Risk Assessment

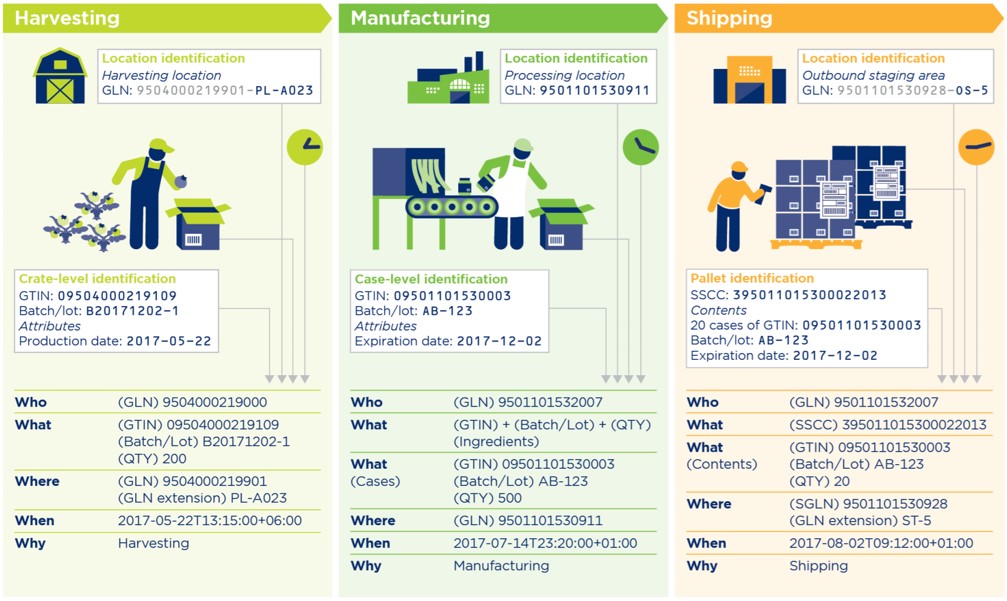

Traceability

Full ‘farm-to-fork’ traceability enabled by GS1 Standards

The following modules and features contribute to full traceability capability:

- GTIN/UPC – class level identification

- Formulation / Ingredients / Raw Materials

- Packaging – multi-level

- GLN – location

- Production Line

- Equipment

- Case identification – Serial Shipping Container Code (SSCC)

- Case receiving (SSCC, GTIN/UPC)

- Case shipping (SSCC, GTIN/UPC)

- Case consumption level

- Batch/Lot creation : Batch ID, Product GTIN/UPC, Production Date, Expiry Date

- Batch/Lot fulfillment, Raw Material assignment : Case (SSCC)

- Inventory update

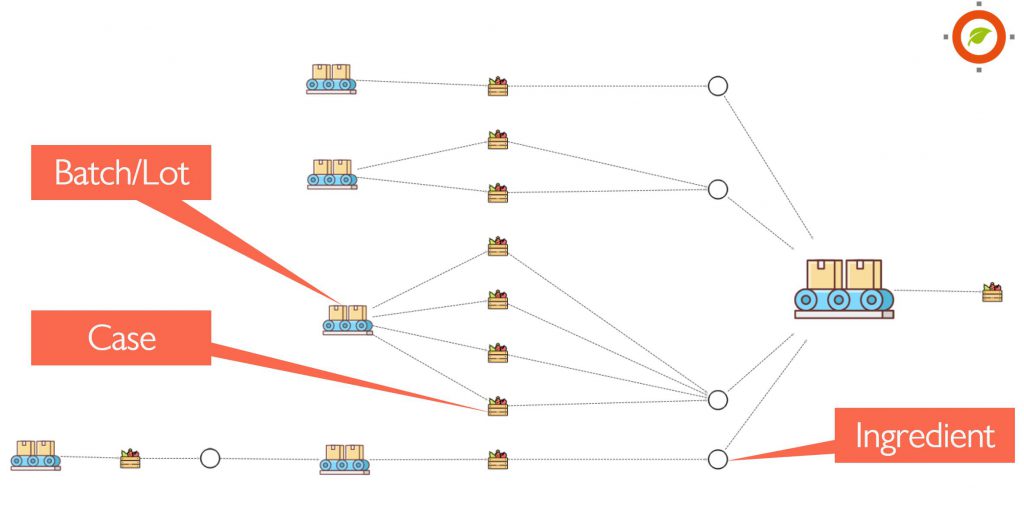

The result is full traceability ‘farm-to-fork’, from Farmer’s/Grower’s Batch/Lot to Cases of Finished Good, Serial Number identified (SSCC)

- Upstream traceability : “Where are all my ingredients coming from?”

- Downstream traceability : “What Products/Cases are impacted by this Ingredient/Batch”?

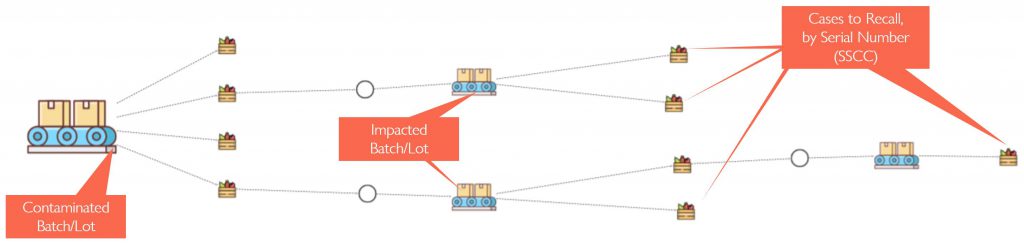

Recall

SCOPE is the antidote to industry’s worst nightmare

The aggregation between Supply Chain Data (Supplier-Manufacturer-Retailer), Product Master Data (formula, ingredients, raw materials) and Transaction/Production Data and Events (Orders, Batch/Lot, Cases, Shipping, Receiving etc) enables unprecedented Traceability and Recall capabilities based on current, trusted data:

- Back-tracking (trace) contaminated Product/Case to the root cause Raw Material production Batch/Lot (Top-Down)

- Instant tracking from contaminated Raw Material Batch/Lot to Finished Product Batch/Lot/Case (Bottom-Up)

- Instant impact analysis (ex. Find all Products using Raw Materials processed in a particular Plant/Line)

- Quarantine : Product (GTIN/UPC), Plant/Line (GLN), Organization (GLN), Batch/Lot (ID), Case (SSCC)

- Instant notification of all impacted parties (Suppliers, Manufacturers, Retailers, Food Safety Agencies etc)

SCOPE can identify the contaminated Batch/Lot and Cases with highest accuracy and precision, in record time (virtually instant)

- Minimize and contain the impact of Recalls

- Compliance with ever growing regulations

- Consumer protection

- Brand protection

Beyond Label – Customer level transparency

SCOPE ‘BeyondLabel’ mobile application brings full transparency to consumer’s fingertips, when needed, where needed

Full transparency by leveraging up-to-date Product Master Data enables features and capabilities that are unique to SCOPE

- Scan Products (in-store), view extended Product Master Data

- Favourite Products

- Product Ratings

- Product Enquiries

- Receive Product Notifications (Recalls, Sale)

- Maintain Consumer Nutrition Profile (specialty foods, diets, allergies, age etc)

- Product discovery / match per consumer profile / templates

Benefits

- Empower consumers to make better nutrition decisions

- Consumer active participation to Food Value Chain

- Consumer protection

- Helps building and maintaining Brand loyalty

75% consumers are more likely to switch to a brand that provides more in-depth product information

Food Marketing Institute:The Transparency Imperative – Product Labeling from the Consumer Perspective

Integration

SCOPE is designed to work within an integrated eco-system

SCOPE is a platform for Data

- Authoring

- Collection

- Aggregation

- Publishing

SCOPE is designed to work in eco-system with other platforms – such as:

- Customer PLM/ERP

- GS1 ECCnet

- Blockchain networks

Integrated Quality Process

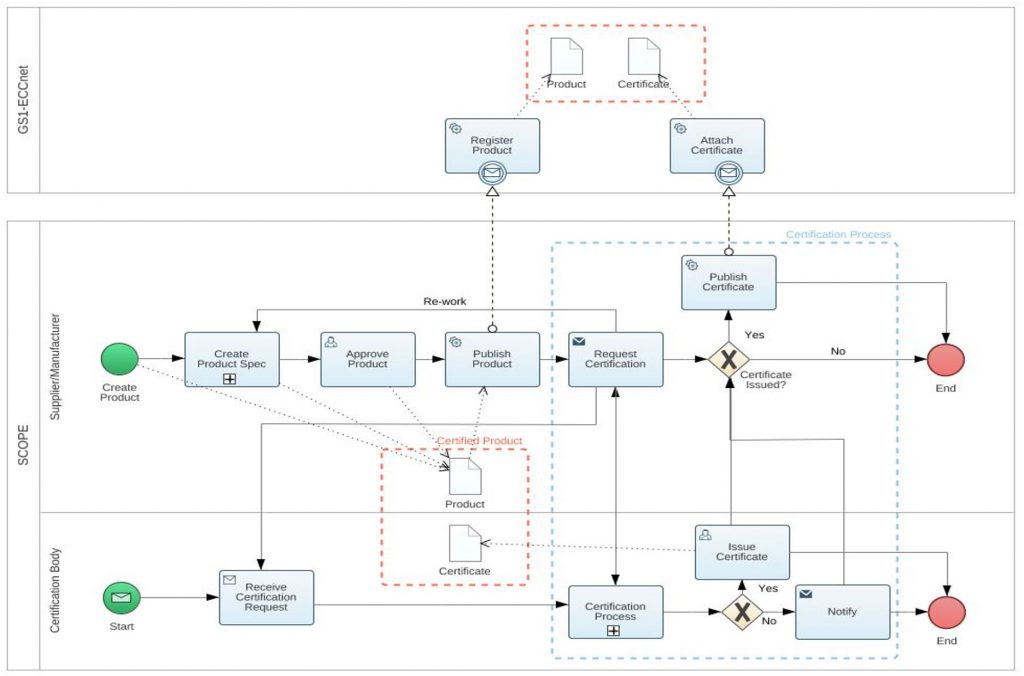

Trusted third-party certification process

As direct participants into the Value Chain, Certification Bodies, Science Analysis Labs and Inspection Agencies have direct access to the Master Data – Product, Plant, Organization

Certification, Laboratory Analysis and Inspection Processes are driven by automated workflows

The resulting artifacts are managed, attached to the Master Data, available and visible to the entire Value Chain, yet secured and protected from tampering

The certification results can be published to any trusted publishing platform (ex GS1 ECCnet, Blockchain, etc)

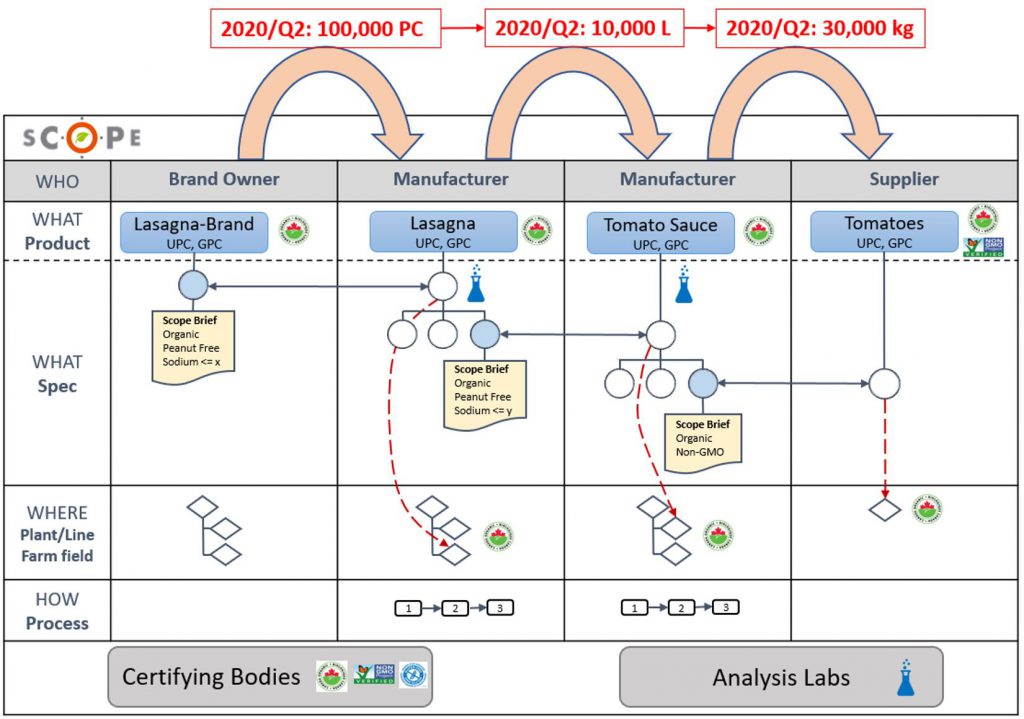

Demand Forecast Propagation

Propagating Demand Forecast across value chain enables Supply Chain Optimization and helps securing fulfillment

Retailer predicts customer demand, then demand is propagated upstream on the Supply Chain, enabling

- Supply Chain Optimization

- Production Planning

- Inventory Management

- Minimize stocks

- Capacity Planning

- Manpower Planning

- Early detection and elimination of supply bottlenecks

- Secure fulfillment